PTG was able to offer support to University of Nevada Las Vegas’s Baja team – Rebel Racing – by way of of a titanium donation. We provided the team with 6AL-4V titanium bar and plate, Grade 2 titanium sheet and plate, and 6AL-4V Eli bar. Tian Chen, the team’s Project Manager, gives us a detailed report on why the team chose titanium and their experience using it. We’re so proud of the accomplishments this fairly young team has made and can’t wait to see how their car does in the fall! (more…)

Blog

Focused on quality,

built around service

-

Sponsorship Report from UNLV’s Baja Team Rebel Racing

-

Titanium Donation to Harding University’s Baja Bison Team

This is the first year we’ve been able to support Harding University’s Baja SAE team, Baja Bison. Zach Charette, Co-Captain of the team, gives some insight below as to why they chose titanium and any issues the team ran into. We wish them all the best as they go into the competition phase.

PTG: Tell me a bit about your team and your role on it. What kind of experience have you gained being a part of the Baja SAE program?

Zach: The Harding University Bison Baja team is a relatively young team, competing in its first competition in 2013. However, this team has grown tremendously throughout the 7 years of competing. This tight knit group of peers is willing to work hard and have fun while doing it. I was the 2019-2020 Co-Captain of the team and recently elected to be the 2020-2021 Captain. I was also in charge of the research and development and manufacturing side of our operation. During the 2018-2019 competition season, I was the brake system lead. Throughout my 3 years on the team, I have gained wonderful experience in problem solving and overcoming challenges. The Baja SAE program has provided me with industry insight that, otherwise, I would not have. I am grateful for the knowledge and friendships gained through this program.

-

Titanium Donation for Northwestern Baja Racing

We’ve had the privilege of working with Northwestern Baja Racing team for the second year in a row. They may not be racing this year but they gained some valuable experience machining our donated titanium before having to put their build on hold. JD Slattery is the new Project Manager for the team and he explains why they chose titanium again and some minor difficulties they ran into.

-

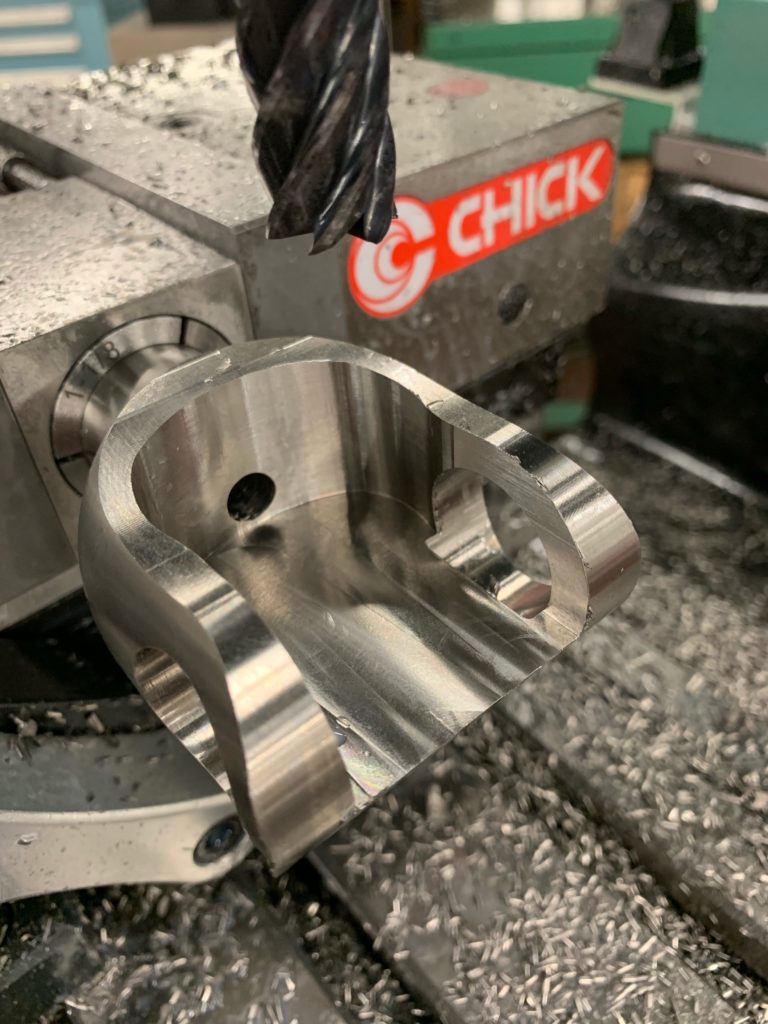

Titanium Donation Provides Valuable Practice for Chico State’s Baja SAE Team

SAE competitions look a little different this year with the COVID19 pandemic. All in-person competitions were cancelled and some were moved to an online platform. With state restrictions and lock-downs, Universities across the country had to cancel classes and students were prevented from continuing work on their vehicles. However, before the lock-downs, some teams were able to start the machining and building process. Perry Cheney from Chico SAE Baja’s team, Wildcat Racing, explains the process of machining the titanium and how they were able to get valuable practice before working on and completing their own parts. (more…)

-

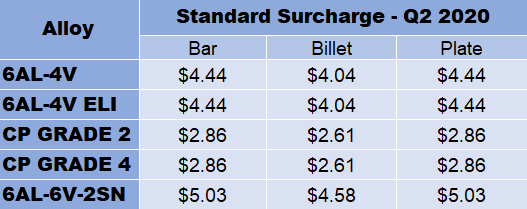

Q2 2020 ATI Surcharges Published

-

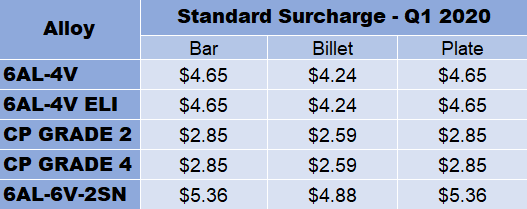

Q1 2020 ATI Surcharges Published

-

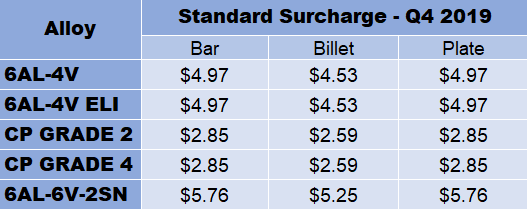

Q4 2019 ATI Surcharges Published

-

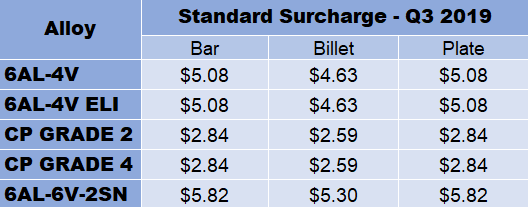

Q3 2019 ATI Surcharges Published

-

Pennsylvania College of Technology Baja SAE Team Chooses Titanium Over Aluminum

Machining 6AL-6V-2SN 2.52″ Dia titanium round stock into a universal axle set. -

Material Donation for San Jose State University Baja SAE Team

This is the first year we’ve been able to work with SJSU’s Baja SAE Team. We provided them with 6AL-6V-2SN 3.6500″ Dia and 4.0560″ Dia. It’s exciting to see everything they’ve done with it and how it has benefited the vehicle and the team this year. Lauren Cook, a Mechanical Engineering Major, tells us a little about the team and how the used the titanium to their advantage.

San Jose State University SAE Baja Team Photo

Categories

Archives

- January 2026

- November 2025

- July 2025

- April 2025

- January 2025

- October 2024

- July 2024

- April 2024

- January 2024

- October 2023

- July 2023

- April 2023

- January 2023

- October 2022

- July 2022

- June 2022

- April 2022

- January 2022

- October 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- January 2021

- December 2020

- October 2020

- July 2020

- June 2020

- May 2020

- January 2020

- October 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- January 2019

- December 2018

- October 2018

- July 2018

- April 2018

- February 2018

- January 2018

- December 2017

- October 2017

- July 2017

- June 2017

- April 2017

- January 2017

- October 2016

- July 2016

- April 2016

- January 2016

- October 2015

- September 2015

- August 2015

- July 2015

- May 2015

- April 2015

- March 2015

- January 2015

- October 2014

- January 2014